What Are Proprietary Ring Topologies in Automation Networks?

Contributed By DigiKey's North American Editors

2021-05-04

Network topology in the context of industrial automation and IoT primarily refers to the arrangement of hardwired communication connections between nodes and devices (such as sensors, actuators, smart motors, drives, and controllers) as well as switches, hubs, and gateways. The network topology used for a machine or larger plant installation determines:

- System communication stability and speed

- The amount of redundancy and recovery time an industrial network possesses

- The all-important connection recovery ability (after failure of some link in the network)

This article explains several network topologies including various ring topologies as well as a few proprietary topologies and where they’re used.

Figure 1: Shown here are the main families of industrial-network topologies. (Image source: Design World)

Figure 1: Shown here are the main families of industrial-network topologies. (Image source: Design World)

More on industrial network topology types

The topology of an industrial-automation network is the way network components classified as links (cable connections in wired arrangements) and nodes are arranged relative to one another. Nodes are devices that may serve as either redistribution points or communication endpoints. In contrast, links are the means through which nodes connect — whether wired or wireless. Links can be:

- Simplex — only allowing one-way communication

- Duplex — allowing simultaneous communications in both directions

- Half-duplex — allowing communication in either direction … but only one way at a time

A network’s topology is the way in which the nodes are connected by the links. Arrangement abounds.

Bus network topology: Networks with a bus topology have one main “track” of cable (known as the bus) to which each node independently connects or “drops” as it’s called in many industry references.

Star network topology: Networks with a star topology are centralized around one node in the form of a hub. Then the other nodes connect to the hub via their links. A star topology also has some advantages for power saving because individual devices which only transmit intermittently can be powered down with only the hub requiring continuous power.

Mesh network topology: Networks with a fully connected topology connect each node to every other node. In much the same way, networks with a mesh topology (like fully connected arrangements) are based on decentralized connections … but don’t require that every pairing of nodes be connected. Setups that don’t have every node connected to every other one are sometimes called partially-connected mesh networks.

Wireless networks often use a mesh topology, as these are robust and secure — and reduce power consumption … a useful feature for networks having battery-powered nodes. Mesh networks can also improve network range for a given amount of wiring because individual links can be shorter than the network as a whole. That’s beneficial to large IoT networks with many low-power sensors. Perhaps most importantly, networks with a mesh topology offer the highest flexibility and redundancy of any option — especially if fully connected. One caveat is that recovery from link failure can be slow because the system must find a new path through the mesh — potentially necessitating the reconfiguration of ports around the broken link. For wired networks, the additional cabling and ports also make the mesh topology more expensive.

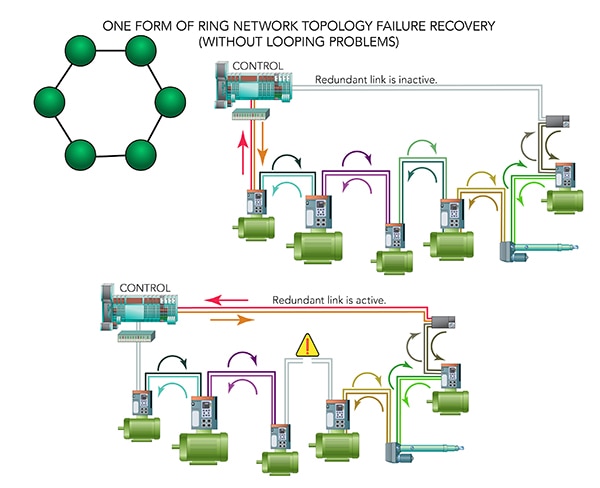

Ring network topology: Networks with a ring topology link each node to two adjacent nodes in a sequence that forms a ring. This is also known as a redundant ring because one link can be disabled until it’s needed.

Deeper dive on ring topology for industrial automation

Networks with a ring topology have good data transfer rates and recover quite quickly from link failure. Cable costs are also relatively low. No wonder ring topologies are generally the leading choice for wired industrial automation networks. With one redundant link disabled, the ring effectively becomes a line … providing fast and efficient communication. During a link failure, there’s no complex rerouting. Instead, a redundant link is simply activated — and all other links continue using the system’s default port routes.

Consider common ring-topology permutations in transmission control protocol (TCP) and user datagram protocol (UDP). With the TCP and UDP IP protocols, internet connections are possible because every device has an IP address. These IP addresses allow the system to route data packets from one address to another. Packets contain the actual data along with additional information in a header that includes the destination IP address.

TCP (often called TCP/IP) controls how data packets are reassembled at their destination. The prerequisite for this to work is having communication from both the sender and receiver. The sender includes sequence numbers in the header, and the recipient must return a message acknowledging packet receipt. If packets aren’t acknowledged, they’re resent. Devices also check packets for errors using checksums in each packet header. This TCP process ensures reliable data exchange at the expense of relatively slow to-and-fro communication processes. In contrast, UDP (the newer IP protocol) allows simpler and faster data transfer between IP addresses. Recipient devices aren’t required to acknowledge receipt of packets, so speed is faster at the expense of slightly degraded reliability.

Redundancy challenges and supplemental solutions

Network management protocols in Ethernet-based systems complement redundancy features to ensure efficient data while avoiding problematic bridge loops and the broadcast radiation they induce. Basically, bridge or switching loops are unnecessarily and problematically repeated data transmissions. These travel through duplicate connections between devices — occurring when a network has multiple pathways between two communicating network nodes.

Figure 2: In industrial automation, ring topologies are speedy and provide rapid recovery from link failure. (Image source: Design World)

Figure 2: In industrial automation, ring topologies are speedy and provide rapid recovery from link failure. (Image source: Design World)

Bridge loops can cause repeated data rebroadcasting, which in turn causes network overloading and drastic network slowdowns. The problem is most likely to arise in systems with lots of redundancy.

Link aggregation uses parallel Ethernet cables and ports to increase bandwidth and hasten recoveries. This means when a link fails, the connection isn’t lost … but some data may be lost — and bandwidth is reduced. Cables usually fail from some mechanical damage, the parallel cables should be routed along different paths, significantly increasing installation cost. This simple approach is standardized as the Link Aggregation Control Protocol (IEE 802.1ad).

It’s possible to maintain the advantages of redundancy while avoiding bridge loops. Here, the solution is topologies having parallel physical loops complemented by the ability to selectively disable links through use of a network-management protocol. Then if an active link fails, the logical topology expands to include one of the redundant links — and rerouting around the failed link. A spanning tree protocol (STP), rapid spanning tree protocol (RSTP), and a variety of proprietary ring protocols all provide this network-management function. Note that a spanning tree is another name for the loop-free logical topology created in these protocols; links not part of the spanning tree are disabled.

STP and RSTP work with both mesh and ring topologies and deliver suitably quick recovery times for most applications. That said, the most demanding industrial automation applications often demand extremely fast recovery times only possible with proprietary ring protocols.

Sampling of proprietary ring protocols

As the name suggests, proprietary ring protocols are specific to manufacturers of network hardware. For example, certain Red Lion N-Tron switches use the N-Ring proprietary ring protocol. These proprietary protocols control network loops and handle link failures, providing an alternative to STP or RSTP.

As detailed earlier, ring topologies are primarily used for physically wired industrial-automation networks for their low latency and ability to provide top reliability — as well as the fastest data-transfer and link-failure recovery rates available. Redundancy is key to recovering from link failures. The catch here is that redundancy can cause issues with the problematically repeated data of looping. Preventing this problem necessitates network protocols capable of loop prevention and rapid link-failure recovery — especially for industrial automation operations unforgiving of downtime. Proprietary ring protocols are often the most suitable choices for such applications needing to maintain quick failure-recovery times.

Consider a few of the most widely used proprietary ring protocols.

HiPER ring was released as a proprietary ring protocol in 1999 by Hirschmann and Siemens. It’s now standardized in IEC 62439 and has the generic name Media Redundancy Protocol (MRP) protocol. It can support up to 200 nodes. Although the standard version has a recovery time of 500 msec, Fast HiPER ring has a claimed recovery of a much more competitive 60 msec.

Resilient Ethernet Protocol (REP) is a Cisco proprietary protocol that’s also used by Rockwell Automation and Westermo. REP provides fast and predictable network behavior and has claimed recovery times as low as 20 msec. Some limitations are that REP isn’t plug-and-play and it doesn’t automatically prevent loops. Instead, REP must be properly configured to deliver these functions. REP works by creating collections of ports chained together — in sequences called network segments.

X-ring is Advantech’s proprietary ring technology, with perhaps the fastest claimed recovery time of just 10 msec. The caveat here is that X-ring is limited to relatively small networks with 20 or fewer nodes.

Red Lion’s proprietary N-Ring protocol mentioned earlier has a 30-msec recovery and the ability to support large networks — with up to 250 nodes possible.

There’s a reason for the rather wide range of speeds listed above. Although TCP and UDP network protocols have slightly different speeds, an industrial network’s topology and management protocol have a much more significant impact on network speed. For example, STP redundant-ring networks have recovery speeds of 30 to 90 sec on TCP and 10 to 50 sec on UDP; RSTP reduces these values to between one and three seconds. Recovery times for mesh networks are even higher. In contrast, certain proprietary ring networks can recover from link failures in just 0.3 sec on TCP … or 0.2 sec on UDP. In fact, select manufacturers claim much better recovery times for their proprietary ring networks … sometimes to within 10 msec.

Conclusion on ring topologies in industrial automation

Ring topologies are common for wired industrial automation networks. Their low latency and top reliability are often complemented by proprietary methods of preventing looping and handling link failures better than traditional STP or RSTP.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.